Breaking Magnets

Magnets are fragile

Of all the magnet concepts we cover, the fragility of neodymium magnets is one of our most challenging topics. For those unfamiliar with handling powerful magnets, learning how easily they are broken can come as an unwelcome surprise.

It's easy to assume that these magnets should be as strong as steel, especially with their shiny, metallic, nickel plated surface. Unfortunately, that assumption couldn't be further from the truth.

We usually brag about the magnetic strength of neodymium magnets. Let's take a look at their mechanical strength, learn why they are not as strong as steel, and see how we can handle them safely without damage.

Common metals are ductile, but sintered magnets are not.

Many common metals are fairly ductile. If a material is ductile, that means you can bend or reshape it before it breaks. Steel or aluminum are ductile metals that many of us have experience handling. For example, you can bend a steel paperclip into a different shape. You can deform the steel without it breaking.

This isn't true for non-ductile materials like glass or ceramic. You can't bend a ceramic coffee mug! If you try bending a neodymium magnet, it breaks. Neodymium magnets are more like a ceramic than a piece of steel.

Allowing magnets to hit each other is bad.

Let's keep comparing steel and coffee cups to keep the analogy going. It's OK to bang two pieces of steel together. If you slam two coffee cups together, you expect something to break. Fortunately, coffee cups aren't normally attracted to one another like magnets!

Magnets are like coffee mugs that are attracted to one another. If you let them slam together, they can reach some incredible speeds just before impact. You might think that metallic-looking magnets can slam together a little, but that impact can be more like tossing your coffee mug onto the sidewalk.

We've made a number of exciting videos slamming really big magnets together, usually breaking something along the way. Don't be fooled, though, it's not just big magnets that can break with an impact. You can break smaller magnets just as easily. Check out the video below to see some slow motion footage of us breaking magnets. Even with these modestly sized disc magnets, you can see failures just from the attractive forces between them.

FYI, they don't always break.

If handled carefully, some contact and impact between magnets can be OK. They don't just instantly fly apart the moment they touch. See our earlier article about How to Separate Strong Magnets.

In fact, we deliberately stacked the deck against us to make that video. Just two magnets attracting towards one another are less likely to break than one magnet attracting to a big stack of magnets. The stack of magnets provides greater magnetic attraction, increasing the impact speed and the chances of failure.

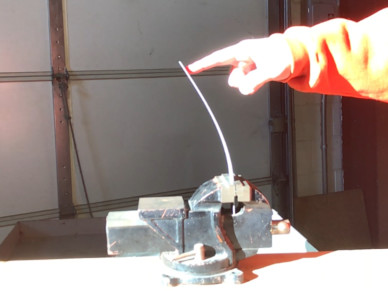

Sometimes, though, magnet damage is not an all-or-nothing thing. It's possible to damage a magnet without breaking it. This can be mistaken for a plating problem.

Let's say two strong magnets slam together and hit. They might hit on an edge with a lot of force, but not enough to crack them in half. Check out the damage from this impact.

What's going on here? Is the nickel plating defective? It looks like it's peeling away from the magnet!

In fact, the hard, brittle magnet material underneath the plating was crushed a little bit by the impact. The more ductile nickel plating retained its shape and continuous surface. It's just bubbled up a bit over the once-solid magnet surface beneath.

This isn't a plating defect; it's damage to the underlying magnet material. The impact has literally crushed some of that magnet material into dust underneath the plating.

Unboxing magnets

What should you do with all this information? Use care when unboxing your order of magnets. They come carefully wrapped and stuck together. Larger magnet sizes might have spacers between them to help make separation easier, but they are still quite attracted to one another.

See our article about How to Separate Strong Magnets for advice and tips on handling them. Do not try separating magnets with pliers or a hammer.

It can be surprising how far apart these magnets can start attracting towards one another. When setting one magnet down, make sure it is far from other magnets. Excessive distance is your friend.

Also consider putting some non-magnetic spacers between your magnets while handling them.

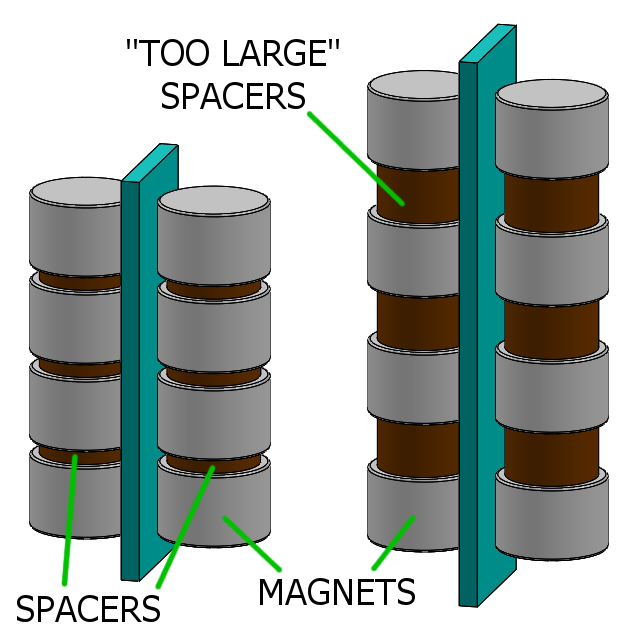

Would Bigger Spacers Make Things Easier? Not so much.

Would increasing the size of the spacer between strong magnets help? Handling and separating strong magnets is difficult, so wouldn't a larger spacer between them make it easier?

Yes and no. While a bigger gap between two magnets does reduce the force, magnet safety isn't quite so simple as that.

When we package strong magnets with a non-magnetic spacer, it can be easier to separate them. We choose the size so that the attraction force is still fairly strong, though. We do this deliberately for multiple safety reasons.

Consider this: Two strong magnets stuck together are hard to get apart. If someone tries pulling them apart, they would find it difficult. Hopefully, they'll get help if they're not sure how to do it.

If magnets are spaced very far apart in a box, they would be like a loaded mousetrap waiting to spring shut. If some unsuspecting person opened the box, they could find a nasty surprise waiting to pinch their finger, or worse.

The challenge gets even more complex with more magnets. We package stacks of magnets with poles in an alternating fashion to comply with shipping regulations, reducing stray magnetic fields outside the package. If excessively large spacers were used within the stacks, it could make the side-to-side attraction greater than the pole-to-pole attraction within the stacks. This usually results in a tangled, chaotic mess when you try separating them.

Studying all the various force interactions in a package of magnets could probably fill several PhD thesis papers. We'll skip that for now and get back to work packing your next order of magnets.