Frequently Asked Questions About Neodymium Magnets

Answers to all of your neodymium magnet questions!

FAQ Categories

General

-

Is one pole stronger than the other?

No, both poles are equally strong.

-

I am using another online magnet pull force calculator. Why is the pull force value from the calculator different from K&J Magnetics' pull force?

Most other online calculators are based on theoretical formulas, which are notoriously inaccurate, especially for very large or very small sizes. Our fanatical engineers have worked long and hard in the laboratory developing our online calculators that are VERY accurate based on thousands of test cases. Our pull force and magnetic field density calculators can be found here: K&J Magnet Calculator.

-

Which is the strongest type of magnet?

Neodymium (more precisely Neodymium-Iron-Boron) magnets are the strongest permanent magnets in the world.

-

Can you supply monopole magnets?

No, we don't, nor does anyone else, because they don't exist. All magnets must have at least two poles.

-

Does stacking magnets together make them stronger?

Yes, two or more magnets stacked together will behave exactly like a single magnet of the combined size. For example, if you stacked two of our 1/8" thick D82 disc magnets to form a 1/4" thick stack, the two magnets would have about the same magnetic strength as the 1/4" thick D84 discs. This is described in more detail in the second half of our article about Doubled Forces.

-

What does

We use the description "Magnetized thru thickness" to identify the locations of the poles on our block magnets. The thickness is always the last dimension listed for block magnets. If you take one of our block magnets and place it on a flat surface with the thickness dimension as the vertical dimension, the poles will be on the top and bottom of the magnet as it sits. For example: Our BX082 blocks are 1" x 1/2" x 1/8" thick. If you place one of the blocks so it is on a flat surface with 1/8" as the vertical dimension, the poles will be on the top and bottom as the magnet sits. This means the poles are located in the middle of the 1" x 1/2" sides. Click here for Magnetization Directions Illustrated.

-

What materials do magnets attract?

Ferromagnetic materials are strongly attracted by a magnetic force. The elements iron (Fe), nickel (Ni), and cobalt (Co) are the most commonly available elements. Steel is ferromagnetic because it is an alloy of iron and other metals.

-

What materials can I use to block/shield magnetic fields?

Magnetic fields cannot be blocked, only redirected. The only materials that will redirect magnetic fields are materials that are ferromagnetic (attracted to magnets), such as iron, steel (which contains iron), cobalt, and nickel. The degree of redirection is proportional to the permeability of the material. The most efficient shielding material is the 80 Nickel family, followed by the 50 Nickel family.

Learn more in our articles about Shielding Materials and MuMETAL.

-

What steel works best?

In our limited pull force testing using various steels, we have not found much difference between different types of low carbon steel. Anything in the 1006-1018 range, or even A36 steel, perform very similarly.

It's stainless steel that can vary much more wildly. Some stainless steels aren't ferromagnetic at all. We've written about this more in our blog article, Stainless Steel.

-

Can you supply a disc/cylinder/ring/sphere magnet with one pole on the outside and one on the inside?

Disc, cylinder, and sphere shapes cannot be manufactured this way. Rings magnetized this way are referred to as, "radially magnetized." While such magnets exist, we are currently not able to supply neodymium ring magnets magnetized this way.

-

Will a magnet with a 20 lb pull force lift a 20 lb object?

Because pull force values are tested under laboratory conditions, you probably won't achieve the same holding force under real world conditions. The effective pull force is reduced by uneven contact with the metal surface, pulling in a direction that is not perpendicular to the steel, attaching to metal that is thinner than ideal, surface coatings, and other factors.

-

Can you supply BH Curves, or Demagnetization Curves for your magnets?

Yes, we have demagnetization curves for our most common neodymium magnet grades. View our BH curve graph.

-

What does a magnetic field look like?

The traditional way of visualizing magnetic fields is to place a magnet near a surface covered with iron filings. If you already have some of our magnets, this is a good experiment to conduct!

We have used Finite Element Analysis software to create magnetic field images for various magnets. View magnetic field images.

-

How is the pull force of each magnet determined?

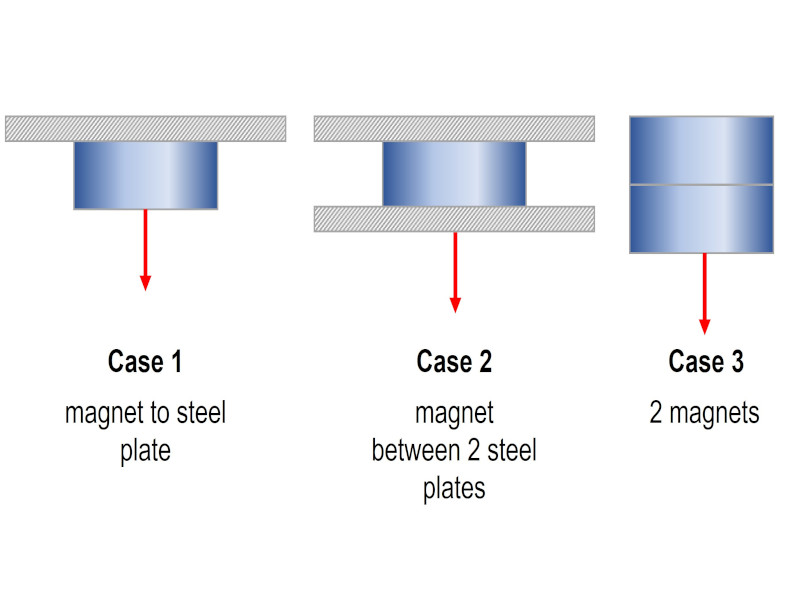

All of the pull force values we specify have been tested in our laboratory. We test these magnets in several different configurations. Case 1 is the maximum pull force generated between a single magnet and a thick, ground, flat steel plate. Case 2 is the maximum pull force generated with a single magnet sandwiched between two thick, ground, flat steel plates. Case 3 is the maximum pull force generated on a magnet attracted to another magnet of the same type.

The values are an average value for five samples of each magnet. A digital force gauge records the tensile force on the magnet. The plates are pulled apart until the magnet disconnects from one of the plates. The peak value is recorded as the "pull force". If using steel that is thinner, coated, or has an uneven or rusty surface, the effective pull force may be different than recorded in our lab.

-

How is the strength of a magnet measured?

Gaussmeters are used to measure the magnetic field density at the surface of the magnet. This is referred to as the surface field and is measured in gauss (or tesla). Pull Force Testers are used to test the holding force of a magnet that is in contact with a flat steel plate. Pull forces are measured in pounds. Fluxmeters and Helmholtz coils are used to measure the magnetic moment. Learn more in our article about Measuring Magnets.

-

How do magnets really work?

This is a very interesting question. It's actually a difficult question to answer well. As the late, great physicist Richard Feynman once said, "How much of an explanation is enough to satisfy you?" To watch him describe the difficulty in answering this question, check out Feynman: How do Magnets Work on YouTube.

If you do want more details, this interesting video: How Special Relativity Makes Magnets Work has a great description about why an electromagnet is attracted to iron.

Their follow-on video, MAGNETS: How Do They Work? is even more relevant to permanent magnets. It addresses how permanent magnets with (seemingly) no current running through them can act magnetic. Ironically, even with that incredible level of detail, at some point they still end up saying, "(Why?) No one knows. We just know that's the way the universe works." Feynman was a pretty smart guy!

-

How can I identify the poles of a magnet?

There are several simple methods that can be used to identify the (Scientific) North and South poles of neodymium magnets.

- The easiest way is to use another magnet that is already marked. The North pole of the marked magnet will be attracted to the South pole of the unmarked magnet.

- If you take an even number of magnets and pinch a string in the middle of the stack and dangle the magnets so they can freely rotate on the string, the North pole of the magnets will eventually settle pointing North. This actually contradicts the "opposites attract" rule of magnetism, but the naming convention of the poles is a carry over from the old days when the poles were called the "North-seeking" and "South-seeking" poles. These were shortened over time to the "North" and "South" poles that we know them as.

- If you have a compass handy, the end of the needle that normally points North will be attracted to the South pole of the neodymium magnet.

- Use one of our Pole Identifier Devices. Also check out our article, Which Pole is North?

Health, Safety, and Electronics

-

Will magnets erase my hard drive or harm my computer?

Not unless you really work at it. While you probably don't want to stick magnets directly to your computer case, having them nearby will not harm your computer. Magnets can damage floppy disks and magnetic tape storage media, so you must keep magnets away from these items. They should not, however, damage any data on your hard drive unless you place a very large and powerful magnet directly on top of the drive. Every hard drive already contains a powerful neodymium magnet, so one moving around outside the case will not affect the data.

We tried scrambling the contents of a running hard drive ourselves, and documented our failure to erase all the data in our article, Hard Drive Destruction

-

I am developing a product using magnets. Do I have to put a safety warning on it about pacemakers/electronics?

While we love answering technical questions about magnets, this one sounds more like a legal question. We're definitely not qualified to provide legal advice.

Again, we are not medical professionals, so we cannot provide firm details on pacemaker issues. As for safety and electronics, it really depends on the application of your product, the size of the magnet(s), how the magnet is used, and where the magnet is located within the product. We recommend providing any warnings that you think may be an issue.

-

What is a safe distance to keep magnets away from pacemakers?

We are not medical professionals, so we cannot offer complete guidance on pacemaker safety, or about any specific medical device. Please consult a physician and/or the manufacturer of your device for this information. We've shared what we do know in our article about Pacemaker Safety.

-

How far away from electronics should I keep my magnets?

This depends on a lot of factors, but as a general rule of thumb, we recommend keeping the distance between magnets and electronics 4" + 1" for every 10 lbs of pull force.

-

Will using magnets on my refrigerator, stove, oven, or microwave harm the appliance?

No, magnets should not harm any of these appliances.

-

Are there health or safety concerns with neo magnets?

There are no known health concerns with exposure to permanent magnetic fields. There may be issues with people with pacemakers or other implanted medical devices handling or being around strong magnets. We are not medical professionals, so we cannot offer complete guidance on pacemaker safety. We've shared what we do know in our article about Pacemaker Safety. Please consult a physician for this information. There are several safety concerns when handling strong magnets. Please refer to our neodymium magnet safety page for complete details.

-

Will magnets harm my electronics?

Maybe...The strong magnetic fields of these magnets can damage certain magnetic media such as floppy disks, credit cards, magnetic I.D. cards, cassette tapes, video tapes or other such devices. They can also damage televisions, VCRs, computer monitors and other CRT displays. Never place neodymium magnets near any of these appliances. As for other electronics such as cell phones, iPods, flash drives, calculators and similar devices that do not contain magnetic storage media, probably not, but it is best to err on the safe side and try to avoid close contact between neo magnets and electronics.

Magnet Handling

-

How do I separate large magnets?

Small and medium-sized magnets can usually be separated by hand by sliding the end magnet off of the stack.Medium-large magnets can often be separated by using the edge of a table or counter top. Place the magnets on a table top with one of the magnets hanging over the edge. Then, using your body weight, hold the magnet(s) on the table and push down on the magnet hanging over the edge. With a little work and practice, you should be able to slide the magnets apart. Just be careful that they don't snap back together once they become separated. For very large magnets (generally 2" and larger), we use a specially made magnet separating tool. You can see pictures of one of these tools as well as instructions on how to build your own on this page: Build your own magnet separating tool.

For a more in-depth explanation, check out our article: How to Separate Strong Magnets which includes a number of short videos.

-

Are there any regulations for shipping magnets?

According to the United States Department of Transportation, the Office of Hazardous Materials Safety, and the International Air Transport Association, the upper limit for shipping magnets by air is a magnetic field strength of 0.00525 gauss measured at 15 feet (4.5 meters) from any point on the outside of the package. If you can measure more than 0.00525 gauss at 7 feet away, it may require labeling as a dangerous good / magnetized material. There are no restrictions on the shipping of magnetized materials by ground. When in doubt, ship magnets by ground transportation.

For a more in-depth explanation, check out our articles: Shipping Magnets and Shipping Magnets II.

-

I have metal dust all over my magnets. How can I remove it?

Using adhesive tape to capture the metal dust is the best way to clean magnets.

Neodymium Specific

-

Do neodymium magnets require a keeper?

No, neodymium magnets do not require a keeper for storage like Alnico magnets.

-

Are your Neodymium Rare Earth Magnets RoHS compliant?

Yes, our magnets are fully RoHS compliant, meeting the European Parliament Directive entitled "Restrictions on the use Of Hazardous Substances" (RoHS). This Directive prohibits the use of the following elements in electrical/electronic equipment sold after 7/1/2006: cadmium (Cd), lead (Pb), mercury (Hg), hexavalent chromium (Cr(VI)), polybrominated biphenyls (PBBs) and polybrominated diphenyl ethers (PBDEs).

"Access our official RoHS compliance statement by clicking this link: RoHS Compliance Statement (PDF)."

You can also find individual PDF files for each specific magnet on the product detail pages, under the "Downloads" tab.

-

What are neodymium magnets? Are they the same as "rare earth"?

Neodymium magnets are a member of the rare earth magnet family. They are called "rare earth" because neodymium is a member of the "rare earth" elements on the periodic table. Neodymium magnets are the strongest of the rare earth magnets and are the strongest permanent magnets in the world.

-

What are neodymium magnets made from and how are they made?

Neodymium magnets are actually composed of neodymium, iron and boron (they are also referred to as NIB or NdFeB magnets). The powdered mixture is pressed under great pressure into molds. The material is then sintered (heated under a vacuum), cooled, and then ground or sliced into the desired shape. Coatings are then applied if required. Finally, the blank magnets are magnetized by exposing them to a very powerful magnetic field in excess of 30 KOe.

Learn more in our article about How Neodymium Magnets are Made.

-

How strong of a magnetic field is necessary to magnetize a neodymium magnet?

As a general rule of thumb, a peak field of between 2 and 2.5 times the intrinsic coercivity is required to fully saturate a magnet. For standard neodymium magnets, the field required is minimum of 24 KOe, but 30 KOe is usually the minimum used.

-

Can I make a magnet that I already have any stronger?

No, once a magnet is fully magnetized (saturated), it cannot be made any stronger

-

I need a magnet the size of a penny/nickel/dime/quarter. What size do I need?

Here are the dimensions of these coins along with the closest matching magnet that we currently stock:

- US Penny = 0.75" dia. x 0.061": DC1 (0.75" dia. x 0.063")

- US Nickel = 0.835" dia. x 0.077": DE1 (0.875" dia. x 0.063")

- US Dime = 0.705" dia. x 0.053": DA1 (0.625" dia. x 0.063"), DB1 (0.688" dia. x 0.063") or DC1 (0.75" dia. x 0.063")

- US Quarter = 0.955" dia. x 0.069": DX01 (1.0" dia. x 0.063")

- US Half Dollar = 1.205" dia. x 0.085": DX42 (1.25" dia. x 0.125")

- CA 5¢ = 21.2mm dia. x 1.76mm: DD1 (0.813" dia. x 0.063")

- CA 10¢ = 18.03mm dia. x 1.22mm: DB1 (0.813" dia. x 0.063")

- CA 25¢ = 23.88mm dia. x 1.58mm: DF1 (0.813" dia. x 0.063")

- CA $1 = 26.5mm dia. x 1.75mm: DX01 (0.813" dia. x 0.063")

- CA $2 = 28mm dia. x 1.8mm: DX21 (0.813" dia. x 0.063")

-

Can I solder or weld to neodymium magnets?

You definitely cannot solder or weld to neodymium magnets. The heat will demagnetize the magnet and could cause it to catch fire posing a safety risk.

-

Will my neodymium magnets lose strength over time?

Very little. Neodymium magnets are the strongest and most permanent magnets known to man. If they are not overheated or physically damaged, neodymium magnets will lose less than 1% of their strength over 10 years - not enough for you to notice unless you have very sensitive measuring equipment. They won't even lose their strength if they are held in repelling or attracting positions with other magnets over long periods of time.

-

Will neodymium magnets lose strength if they are held in repelling or attracting positions for a long time?

In most applications, the answer is simply "no". If the magnets will be exposed to higher temperatures while in repelling applications, the answer is "possibly". The exact answer is a bit too complicated for a FAQ answer, and requires specifics about the application.

-

What are neodymium magnets used for?

Just about anything you can imagine! Please see our uses for neodymium magnets for a list of some of the applications for these incredible magnets. Read even more in, Magnets Are Everywhere.

-

What does the grade or "N number" of a magnet mean?

The grade, or "N rating" of the magnet refers to the Maximum Energy Product of the material that the magnet is made from. It refers to the maximum strength that the material can be magnetized to. The grade of neodymium magnets is generally measured in units millions of gauss oersted (MGOe). A magnet of grade N42 has a Maximum Energy Product of 42 MGOe. Generally speaking, the higher the grade, the stronger the magnet.

-

How is neodymium pronounced?

From a dictionary: [nē ō dim ē um]. Or, nee-oh-dim-ee-um.

The only real trick to pronouncing it correctly is to treat the 'y' as an 'i'. It is pronounced as if it were spelled "neodimium". -

Can I cut, drill, or machine neodymium magnets?

The Neodymium Iron Boron material is very hard and brittle, so machining is difficult at best. The hardness of the material is RC46 on the Rockwell "C" scale, which is harder than commercially available drills and tooling, so these tools will heat up and become damaged if used on NdFeB material. Diamond tooling, EDM (Electrostatic Discharge Machines), and abrasives are the preferred methods for shaping neodymium magnet material. Machining of neodymium magnets should only be done by experienced machinists familiar with the risk and safety issues involved. The heat generated during machining can demagnetize the magnet and could cause it to catch fire posing a safety risk. The dry powder produced while machining is also very flammable and great care must be taken to avoid combustion of this material.

-

Do I have to worry about temperature with neodymium magnets?

Yes. Neodymium Iron Boron magnets are sensitive to heat. If a magnet heated above its maximum operating temperature (176°F (80°C) for standard N grades) the magnet will permanently lose a fraction of its magnetic strength. If they are heated above their Curie temperature (590°F (310°C) for standard N grades), they will lose all of their magnetic properties. Different grades have different maximum operating and Curie temperatures. See our Neodymium Magnet Specifications Page for more details. Also check out our in-depth article about Temperature and Neodymium Magnets, where we dive into enough technical detail to reveal how this topic is actually a bit more complex. We do stock a range of high temperature magnets.

-

What is the gauss rating of your magnets?

While we've certainly heard this question before, it's not clear what answer you're looking for. A few different magnet properties are specified in gauss. From our Magnet Grades article:

How many Gauss is a magnet?

We're often asked if a magnet “has 10,000 Gauss.” This is a bit of a strange question, since Gauss is a unit of magnetism that can apply to different measurements or magnet properties. A magnet doesn't have one specific amount of Gauss in it. Two common measurements expressed in Gauss are The Residual Flux Density, Br, and the Surface Field.

Residual Flux Density, Br, is the magnetic induction remaining in a saturated magnetic material after the magnetizing field has been removed. Scroll down to the last section of this article for a more detailed explanation.

This number is a material property which is independent of the magnet shape. Grade N42 magnets have a Br of 13,200 Gauss, while N52 magnets can be as high as 14,800 Gauss. See our Specs page for more Br values for various neodymium magnet grades.

The Surface Field is the strength of the magnetic field measured right at the surface of the magnet. It's the field strength you might measure if you could squish a magnetometer's sensor right up against the surface. This number depends on the magnet material, the shape of the magnet and how it's used in a magnetic circuit.

In either case, you can find values for each of these properties on the product pages for each of our magnets.

-

Where can I find documentation or certifications for these magnets?

You can download all documentation and certifications, including REACH, Conflict Minerals, MSDS, Certificate of Origin, Certificate of Compliance, and more on the product description page of the specific magnet you are interested in, under the "Downloads" tab.

-

What is the difference between the maximum operating temperature and the Curie temperature of the magnets?

The maximum operating temperature is the maximum temperature the magnet may be continuously subjected to with no significant loss of magnetic strength. This is 176°F (80°C) for standard grades of neodymium magnets. The Curie Temperature is the temperature at which the magnet will become completely demagnetized. This is 590°F (310°C) for standard grades of neodymium magnets. Higher temperature grades have higher maximum operating temperatures and higher Curie Temperatures. At temperatures between these two points, a magnet will permanently lose a portion of its magnetic strength. The loss will be greater the closer to the Curie Temperature it is heated.

For a more in-depth explanation, check out our article: Temperature and Neodymium Magnets.

-

Are neodymium magnets affected by US Conflict Minerals Law, as made in section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act?

This law requires reporting of the use of columbite-tantalite (tantalum, used in capacitors), cassiterite (used to make tin), wolframite (tungsten) and gold that comes from mines located in the eastern part of the Democratic Republic of Congo. Since neodymium magnets don't usually contain these elements, they shouldn't be covered by this law. Learn more about what elements are used in the manufacture of neodymium magnets in our article: How Neodymium Magnets are Made.

Ordering Questions

-

Can you just put my magnets in a small envelope to save postage?

No. All magnets must be shipped in a box to comply with United States Department of Transportation, USPS, and UPS regulations for the shipment of magnetic materials.

-

Every time I add something to my shopping cart, I get a message that my cart is empty. What do I do?

Most of the time, this is caused by cookies being disabled on your computer. Our shopping cart must be allowed to write a small cookie to your computer to "remember" what you place in your shopping cart. To find out how to enable cookies for your browser, search online for, "How to Enable Cookies."

-

Can I open an account with K&J Magnetics?

We accept Purchase Orders from businesses with approved credit. For additional information, please email us at contactus@kjmagnetics.com.

-

Where can I get a discount code?

You can receive discounts by joining our Mailing List. Our periodic newsletter, sent once a month, contains news, new products and Mailing List exclusive coupons and specials.

-

Can you give me a quote for a stock magnet?

You can view all current pricing and price breaks directly on our website. If you need a formal quote for our magnets, you can create a downloadable PDF directly from our website. Simply place the magnet(s) you want into the online shopping cart. Be sure to put in the correct quantity -- the cart automatically includes discounts based on the number you purchase.

Once you've added all the items you want, navigate to https://www.kjmagnetics.com/cart.asp. Beneath the list of items in your cart, you'll find a link to download your PDF quote. It reads something like:

Need a formal quote? Click here to download a PDF quote of items currently in your shopping cart.

-

I do not want to put my credit card info online. Is there some other way I can pay?

We take every measure possible to ensure that your online transaction with us is secure. You can read more about this on our security policies page. If you still prefer not to order online, there are other ways to place an order with us. See our order and shipping info page for more details.

Plating Questions

-

What is the best adhesive to use with your magnets?

We and several customers have had great success adhering to the nickel-plating using Loctite 39205 (an acrylic adhesive) with Loctite 7380 activator. A Loctite representative also recommended Loctite 3032 (a 2-part acrylic adhesive) with Loctite primer 770. For more commonly found adhesives, we have also had great results using many kinds of epoxy, often sold as "5-minute" epoxy. "Liquid Nails" and "Gorilla Glue" can also work well, and are available in most hardware and home supply stores. It does help to scratch the surface of the plating lightly with sandpaper or other abrasive prior to applying the adhesive. For more information, read our in-depth article: Sticky Business: How to Glue Neodymium Magnets.

-

Do you stock any unplated magnets?

NdFeB material will oxidize if it is exposed to moisture. For this reason, we do not stock any unplated magnets. We can supply unplated magnets as custom order items.

-

I noticed that the plastic- and rubber-coated magnets have a lower pull force than nickel-plated magnets of the same size. Does the plastic/rubber weaken the magnet?

These materials don't "weaken" the magnet, but the volume of magnet material is reduced to allow room for the coatings, which reduces the pull force. The layer of plastic or rubber also creates distance between the magnet and metal surface which also reduces the pull force.

-

How can I protect my magnets from damage due to impact?

We have found that wrapping magnets with a few layers of electrical tape protects them from most damage caused by collisions with other magnets and hard surfaces. Another great way to protect your magnets from damage and the elements is to coat them with rubberized coating. We have created a page with step-by-step instructions on how to do this. We also stock several sizes and shapes of plastic-coated and rubber-coated magnets.

-

Can I paint over the nickel plating?

Yes, you can use any paint formulated for use on metal surfaces. Spray-on paint seems to work best. Roughing the surface first can help improve paint adhesion to the smooth, nickel plated surface. Sandblasting or beadblasting works, as well as an etching primer. Check out our blog article, Painting Magnets, for some more information.

-

What is the difference between the different platings and coatings?

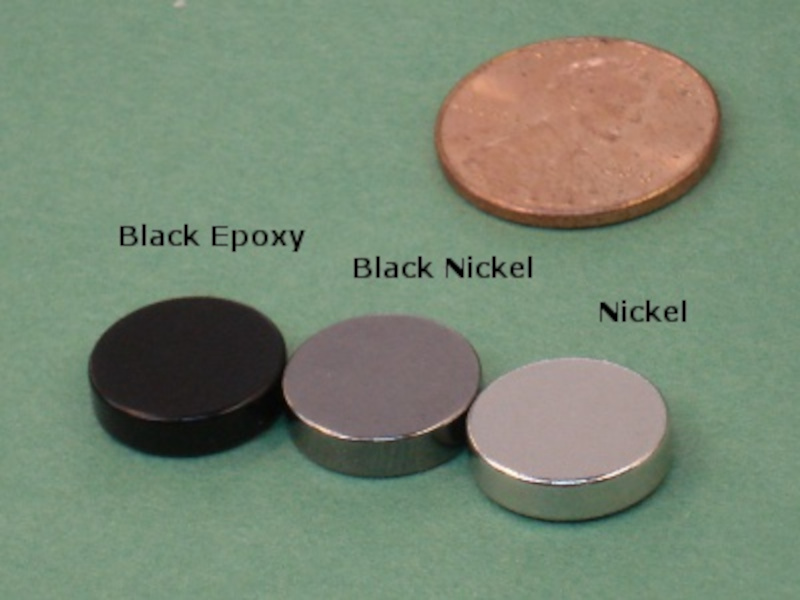

Choosing different coatings does not affect the magnetic strength or performance of the magnet, except for our Plastic and Rubber Coated Magnets. The preferred coating is dictated by preference or intended application. More detailed specifications can be found on our Specs page.

- Nickel is the most common choice for plating neodymium magnets. It is actually a triple plating of nickel-copper-nickel. It has a shiny silver finish and has good resistance to corrosion in many applications. It is not waterproof.

- Black nickel has a shiny appearance in a charcoal or gunmetal color. A black dye is added to the final nickel plating process of the triple plating of nickel-copper-black nickel. NOTE: It does not appear completely black like epoxy coatings. It is also still shiny, much like plain nickel plated magnets.

- Zinc has a dull gray/bluish finish, that is more susceptible to corrosion than nickel. Zinc can leave a black residue on hands and other items.

- Epoxy is basically a plastic coating that is more corrosion resistant as long as the coating is intact. It is easily scratched. From our experience, it is the least durable of the available coatings.

- Gold plating is applied over the top of standard nickel plating. Gold plated magnets have the same characteristics as nickel plated ones, but with a gold finish.

-

Why are most neodymium magnets plated or coated?

Neodymium magnets are composed mainly of Neodymium, Iron, and Boron. If neodymium magnets are not plated, the iron in the material will oxidize very easily if exposed to moisture. Even normal humidity will rust the iron over time. To protect the iron from exposure to moisture, most neodymium magnets are plated or coated.

-

What is the thickness of the nickel (Ni-Cu-Ni) plating?

The nickel plating is actually triple plating of nickel-copper-nickel. The combined thickness totals 15-21μm.

-

I see you supply plastic and rubber coated magnets. Can I get a different size coated?

Maybe. Each of our plastic or rubber coated magnets require its own special mold. A new size requires a new mold, with a one-time cost of $300-$2,500, depending on the size and shape. If you need a large quantity of such magnets, creating a new mold may be worthwhile. If you only need a few, doing your own rubber coating might be more cost effective. Be sure to look through our complete list of Plastic and Rubber Coated Magnets.

Questions about K&J Magnetics

-

Where are you located?

Our main office and warehouse are currently located in Pipersville, PA, about 30 miles north of Philadelphia. We do not have a retail store, nor are we able to accept walk-in customers or pick-ups.

-

What kinds of magnets does K&J Magnetics supply?

We specialize in and only provide sintered neodymium magnets. They are also called rare earth or NdFeB magnets. We are not able to provide other magnet types, like samarium cobalt, alnico or ceramic magnets. -

Do you have a local distributor near me?

We do not have any local distributors of our magnets. All sales are through our website and ship from our location here in Pennsylvania.

-

Do you have a printed catalog?

No, we do not have a printed catalog available. Find information about all of our magnets online, here at our website.

Special Uses/Applications

-

I am looking for the equivalent of a magician's M5/PK5 magnet. Which of your magnets is the equivalent?

The magician's M5 (aka PK5) magnet is the equivalent of our BY0Y08 block magnet.

-

I would like to erase hard drives/degauss tapes. Which magnet should I use?

Magnetic tapes can be erased with a strong magnet. Popular choices include:

We used to think that a sufficiently large magnet would scramble the data on a hard drive. Some recent experiments we have conducted seem to disagree in our Hard Drive Destruction with Magnets article. We don't recommend this method if you must be sure that the data is gone. Physical destruction of the drive is the safest choice.

-

I would like to use magnets for water treatment. Which magnets should I use?

Magnets on the main water line should be of dimensions 1.5 - 2.5 times the outside diameter of the pipe coming in. Larger magnets will provide a stronger and more consistent magnetic field between them. For this application, we often recommend our BY0Y08 blocks. They will work well on any water line up to 1.5" in diameter. Water conditioning works best if you use two magnets, one on each side of the pipe in attracting arrangement. The two magnets in this arrangement create the strongest possible magnetic field between them. It works very well if you have two "shims" which are the same thickness as the diameter of the water pipe. If you tape the shims to either side of the pipe, they will provide a flat surface for the magnets to rest on. The large magnets should hold each other in place across the pipe and shims. The magnets can then be held in place with tape to prevent them from slipping off due to vibration.

Interested in learning more about how magnetic water treatment might work? Check out our Magnetic Water Treatment article, where we discover some surprising facts about this controversial subject!

-

Which magnets should I use for holding pictures and papers to my refrigerator?

For refrigerator magnets, there are many options. Check out our Refrigerator Magnets section, which includes a number of great suggested magnets. We carry a neat line of magnetic thumbtacks.

-

I heard you can repair dents in brass instruments using magnets. How can I do this?

Dent removal is accomplished by inserting a steel ball into the instrument as close to, but smaller than, the diameter of the section of tubing being repaired. The steel ball can be moved through the tube using a magnet on the outside. Working the steel ball over the damaged area will gradually smooth out the dent. A magnet like our DX0X0 will pull out most small- and medium-sized dents, while a larger magnet like our DX8C may be necessary for larger and more stubborn dents. We do carry a line of steel balls that can be used for this application.

-

Which magnets should I use for holding pins/badges through clothing instead of using pins?

For holding average-sized pins and badges, we recommend our D62 disc magnets, as they provide the appropriate amount of pull strength through a wide range of fabric thicknesses.If you will be holding large or heavy pins or badges, or will be holding through exceptionally thick material, then our D72 disc magnets or D82 disc magnets may be necessary to provide enough holding force.

Also check out our Sewing Magnets that are made specifically for use as magnetic closures. They are intended to be sewn inside the fabric, remaining hidden from view.

They come in 3 different sizes and are sold in matched pairs. Also note that some have a thin plastic cover that protects them from moisture, which is an excellent solution for anything that goes through the washing machine.

See our Sewing Magnets Into Fabric article for an example of how to use them. There, we describe how we replaced the Velcro fasteners on a pair of cargo shorts.

-

I need magnets for a binder/brochure closure. Which magnets work for this?

We have many printers and other customers that use our magnets in brochures and binders to hold them closed. The most common sizes used for brochures and binders are our D401, D41, D501, D51, D601, D61, D701, D71, D801, D81 disc magnets, and our B4401, B441, B6301, B631, B661, B821, B841, B8801, and B881 block magnets, but larger sizes can also be used for larger applications.

See our Adhesive Backed Magnets article for a great example of how to do this.

-

Do you sell magnetic sheets?

No, we specialize in sintered neodymium magnets. These are solid, brittle blocks - not like the flexible magnets you might see a business card printed on. We do not sell those kinds of magnetic sheets.

-

Which magnets should I use for holding spice cans to my fridge?

The answer varies depending on the size of the can and the weight of the items being stored. Magnets as small as our D81 discs can be used to hold smaller cans, while magnets as large as our DC2 discs may be required to hold very large cans. Check out our Magnetic Spice Jars article to see our experiences adding magnets to popular glass jars.

-

Can I use neodymium magnets to trigger traffic lights with my motorcycle/moped/bicycle?

This one is a definite "maybe". We have received feedback that magnets as small as our D84 discs have successfully triggered traffic lights, but we have also received reports that magnets as large as our DX8C have failed to trip similar traffic light sensors. It seems that there are different types and different sensitivities of traffic light sensors, and magnets will trigger some, but not all of them. If you have any feedback or good information on this, we would appreciate an email with any details you may have.

-

Which magnets should I use for holding knives to my fridge?

For small knives, small magnets like our B444 cubes are sufficient. For butcher knives and other large knives, we recommend our BX084 blocks. Mid-sized knives can be held to a refrigerator using our B884 blocks. Read our Magnetic Knife Holder article to see how we made a magnetic knife block.

-

What magnets should I use to hold a sunscreen to the windshield of my RV?

We have heard from many customers who use our strong magnets to hold up sunscreens to the windscreen of an RV.

How strong do you need the hold to be? Obviously, this involves many factors, from the size and shape of the shade, to how strong a windstorm you expect to withstand. The key is the thickness of the windshield. A pair of magnets will attract towards each other, but the strength drops quickly as you move the magnets farther apart.

We've heard from a number of people who have made their own, using DC6 magnets inside and waterproof DC6PC-BLK magnets outside. Some commercial products use magnets as large as our 1" diameter DX06 discs.

-

What can I use to remagnetize my refrigerator door seal?

While this technically is possible, we think in most cases it's not a great idea to try re-magnetizing a fridge seal with a neodymium magnet. A lot of times problems with fridge seals come from the seal being dirty or deformed in some way, not because the magnet got weaker over time. Rubbing a neodymium magnet over your fridge seal can either demagnetize the seal completely or weaken it, and end up making the problem worse.

We discuss this in greater detail in our blog, check out Re-Magnetizing Refrigerator Seals for a more detailed explanation.

-

I need a special size/shape of neodymium magnet. Can you supply custom magnets?

Yes, we can supply custom magnets. You can find details on our Custom Magnet page.