How Much Will a Magnet Hold?

Exploring magnet strength in practical applications

1. I see the Pull Forces listed on your website, but what do they really mean?

We get a lot of questions about how much a magnet will pull in a given situation. The answer usually amounts to: it depends! Learn more about our testing methods, what it all means, and how all this information might apply to your specific application.

2. Our Testing & Specifications

The pull force data listed on our product pages and that determined by our magnet calculator come from tireless experimental testing. We test our magnets in very specific loading conditions -- if your situation is different, you should expect different results. First, let's look at how we test and what applications this closely corresponds to.

Shop Neodymium Magnets

Powerful rare earth neodymium magnets for every project or application.

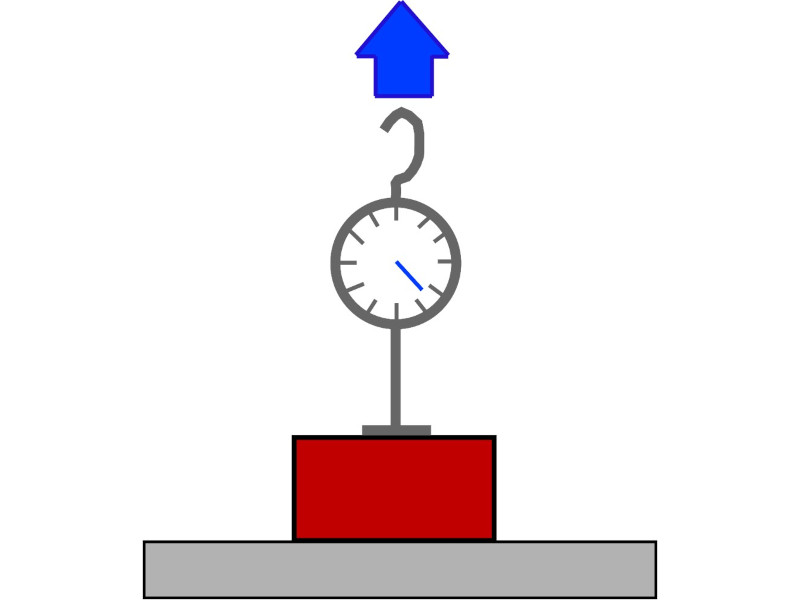

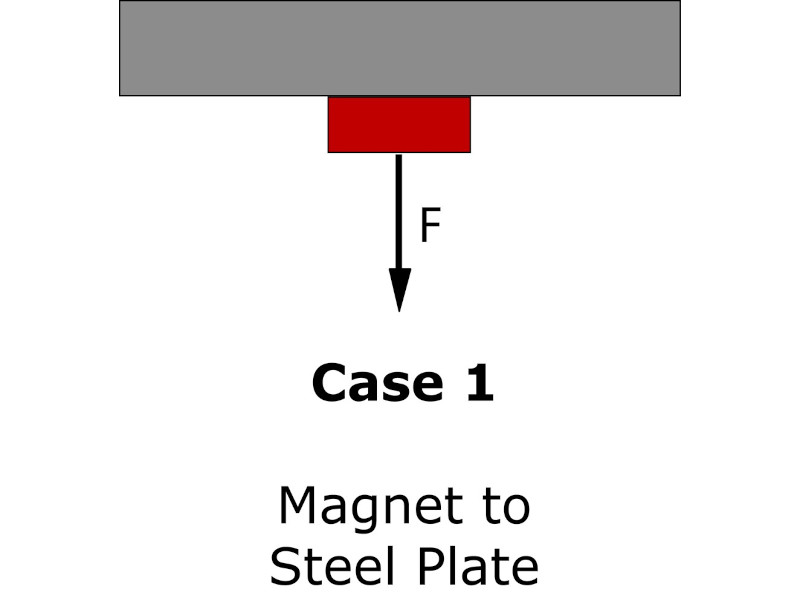

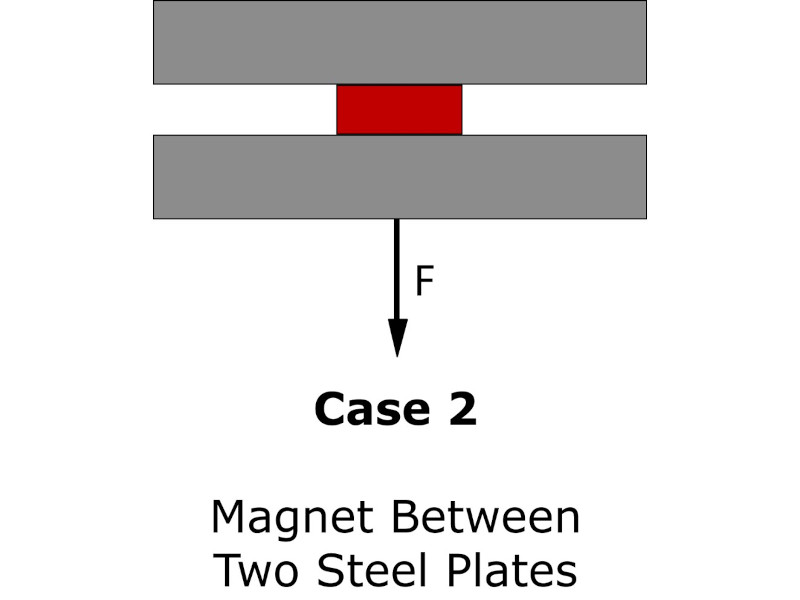

3. Attaching magnets to steel (Pull Force Case 1)

The most basic case is a single magnet stuck to a steel plate. We use a thick, solid steel plate that has been machined to be nearly perfectly flat. It is larger than the magnet being tested. A pull force gauge measures the force required to pull the magnet away from the steel plate.

If you stick your magnet to an overhead I-beam, you should see results just like our Pull Force Case 1 numbers. If you stick a D88 disc magnet to a steel ceiling, and hang weights from it until it lets go, you should see it hold right up to about 14 lbs, as listed.

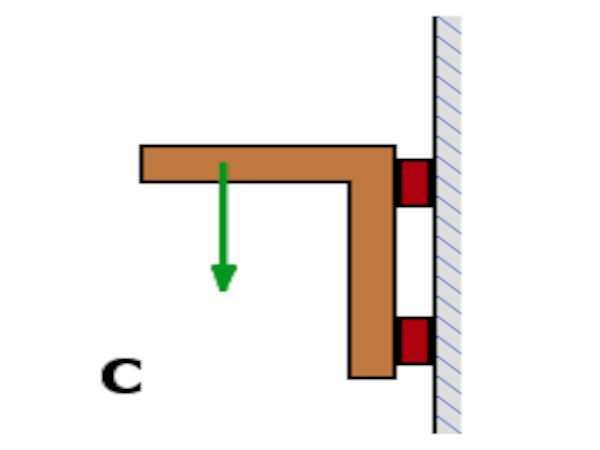

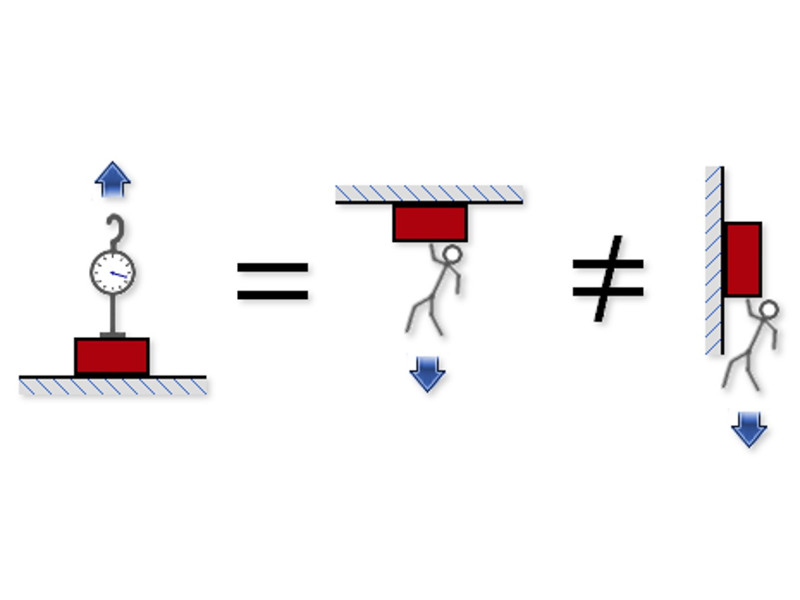

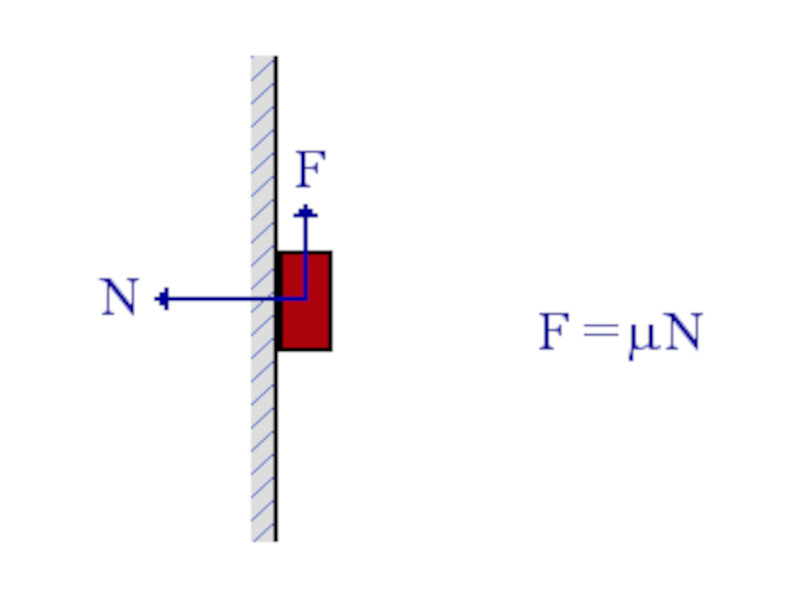

4. Shear friction when hanging magnets

Another typical use is the refrigerator magnet. How much weight will it hold stuck to the door of my refrigerator? Magnets don't pull with any lateral force when stuck to a steel plate. The magnetic force pulls the magnet straight towards the steel door. As gravity tries to pull the magnet down, the friction between the magnet and the door prevents it from sliding.

Only this friction force keeps the magnet from sliding down the face of the refrigerator door.

Why don't we publish numbers for this? Because the friction coefficient varies greatly depending on the two materials and any lubrication that might be there. The paint on your refrigerator might be different than mine. Or perhaps my fingerprints are greasier -- small changes can make a big difference! From the Wikipedia article on the coefficient of friction:

- The coefficient of friction is an empirical measurement – it has to be measured experimentally, and cannot be found through calculations.

Check out this reference for a list of friction coefficients for a number of various materials. Note the disclaimers all over it -- you really have to try it out in your specific application. Being cautiously pessimistic, try starting out with an assumption of 0.1 - 0.25 (which is roughly the friction between a nickel plated magnet and a steel surface) for your coefficient of friction. That is, you might only get 10% - 25% of the listed pull force when loaded this way.

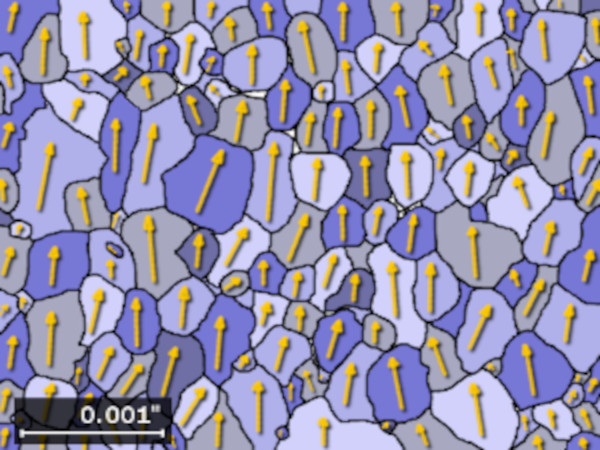

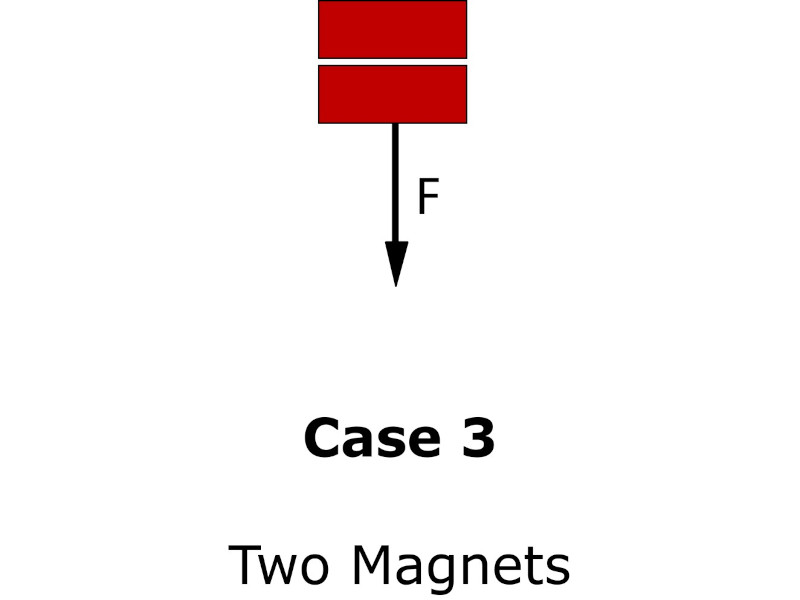

5. A magnet between two pieces of steel (Pull Force Case 2)

On all our product pages, we also provide pull force data for a second type of test called case 2. That's where we sandwich a magnet between two steel plates and pull them apart. For very thin magnets, this can have a big amplifying effect on the pull force. The thinner the magnet, the more pronounced the effect. Once the magnet thickness surpasses its diameter or width, pull force case 2 will not be much stronger than case 1. In most cases, if the magnet thickness is 1" or more, case 2 will equal case 1.

For example, a single D82 (1/2" diameter x 1/8" thick) disc magnet has a pull force case 1 of 6.44 lb. When tested between two steel plates, however, the force required to separate them jumps up to 16 lb! That's a huge difference.

Now, you might not see quite this much of an increase in your own application. We're using very flat, raw steel plates, held quite parallel by our test fixture. It's an ideal situation. Still, these numbers serve as a good example of how any surrounding ferromagnetic material (such as steel or iron) might dramatically affect your results.

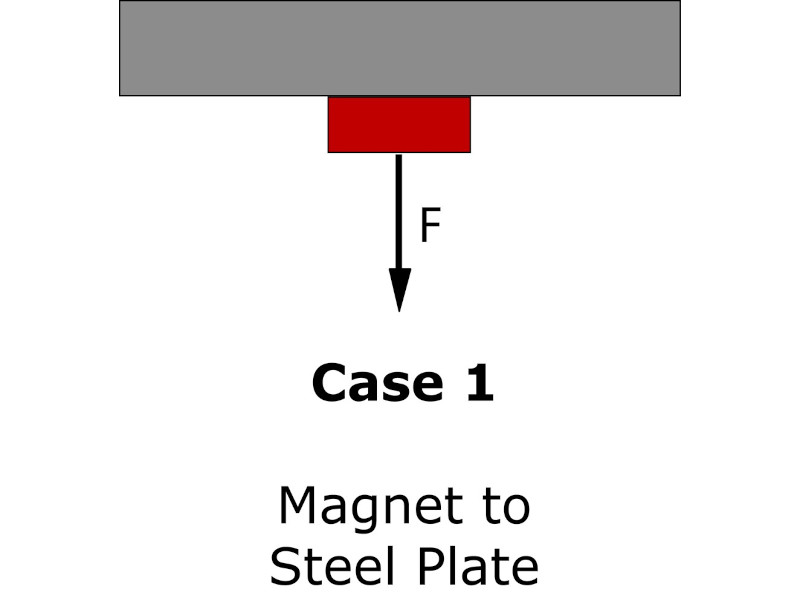

6. Two magnets attracting to each other

Another common usage of neodymium magnets is attaching two magnets to each other to hang pictures on a wall and for many other applications. This is pull force case 3 and can also be found on all applicable product pages.

Similarly to attaching magnets on a stainless steel surface like a refrigerator, two magnets used to hang objects will also lose pull strength due to friction. However, unlike magnets stuck on stainless steel, two magnets will still retain about 50% of the listed pull force.

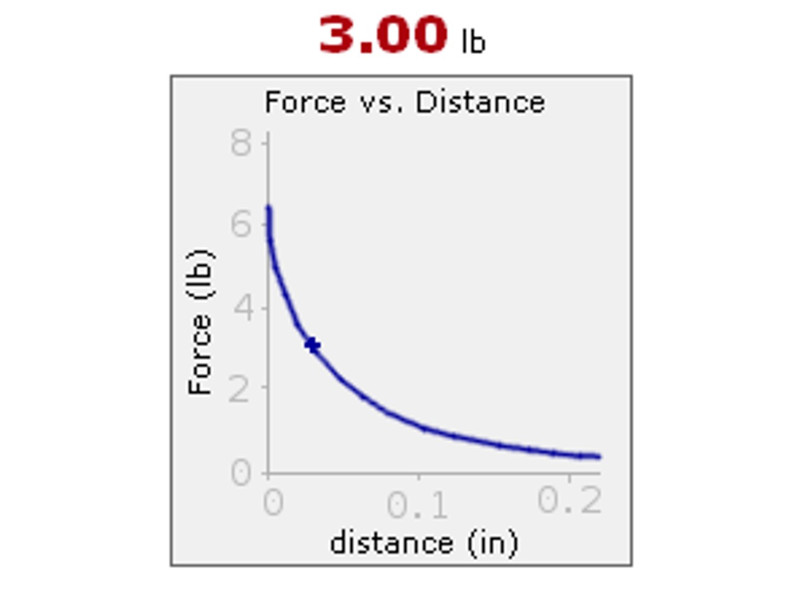

7. Distance matters: how a gap lowers a magnet's strength

The distance between your magnet and what it's sticking to can make a very big difference in the pull force you'll see. Our magnet calc is a handy tool for playing with these numbers.

For example, the D82 magnet pulls with 6.44 lb against a steel plate. Insert 10 pieces of paper between the magnet and the steel plate, and you've now distanced them by about 0.03". The force drops to 3 lb.

All of our product pages such as the D82 product page now include a link to a force vs. distance graph.

8. How to increase magnet strength when hanging things with magnets

We just talked about each pull force case and how a coefficient of friction can lower magnet strength when hanging with things, but we did not mention how to increase magnet strength. Here are some of the top ways that you can make a magnet stronger to help overcome low friction when hanging.

5 ways to increase magnet strength

- Magnet grade: You can upgrade to a stronger grade of magnet. Our strongest grade is N52 and you can browse our wide selection of N52 neodymium magnets to meet your needs.

- Magnet heat resistance: You may be losing magnet strength due to using the magnets in a hot environment past their maximum operating temperature. Check out our high temperature neodymium magnets and learn more in our Temperature and Neodymium Magnets article.

- Rubber coated magnets: Rubber coating on a magnet greatly increases grip strength of a magnet and you can get as much as 75% or more of the listed pull force when hanging. Check out our rubber coated magnets and learn more in our Benefits of Plastic & Rubber Coated Magnets article.

- Adhesive Non Slip Pads: Our adhesive pads offer an anti-slip solution that can be attached to a magnet when hanging on various surfaces to increase a magnet's traction.

- Cleaning the surface: Some surfaces may be covered in oil from our skin, grease or other substances that can lower friction. Cleaning the surface first can help increase friction. Cleaning surfaces is also vital when using any adhesives on magnets. Learn more in our Sticky Business - How to Glue Neodymium Magnets article.

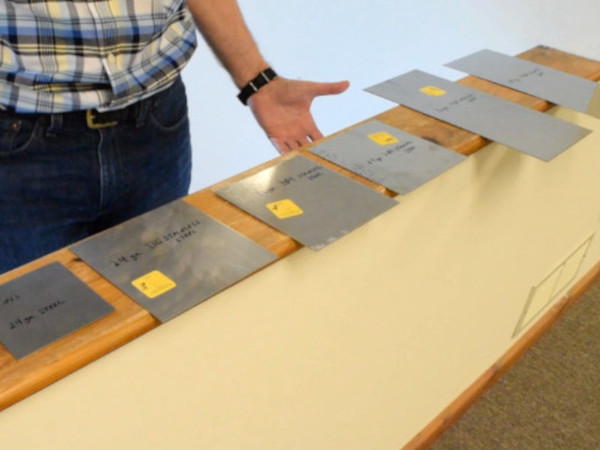

9. Testing to find the best magnets for your use case

While we're available to contact by email to help you choose the right size magnet for your application, at some point you have to get your hands dirty and try it out yourself. While some email pointers can be helpful, you'll ultimately have to try actual magnets in your specific application. Order a few magnets of different sizes and experiment with them. There's no minimum order!

If you're ordering only a few magnets for prototyping purposes, make your shipping dollars count and order a few different sizes. Nothing beats having these magnets in your hands to see what they're capable of. Our sample packages are a great value, and a good way to have a number of different sizes and shapes on-hand for testing in your application.