Eddy Current Magnetic Separation

Exploring eddy currents: separating non-magnetic metals from other materials

1. Separating metals using eddy currents

In this article we will cover how eddy current and magnets are used to separate ferrous metals like iron and steel as well as other conductive metal like aluminum and copper from other materials. This separation is invaluable in many industries as it allows for the removal of scrap and impurities or allows quick sorting of bulk material. If you are unfamiliar with what an eddy current is, you may want to check our Eddy Currents article first.

First we will look at how the differences in separation with and without an eddy current and the advantages eddy currents provide in modern industry.

2. Ferromagnetic separation

Magnetic separation roller with no eddy current

This conveyor belt does not use an eddy current. It utilizes a circular array of block magnets with alternating poles facing outward to provide a strong magnetic field and hold on the material.

This magnetic separation roller works as expected with non-magnetic (aluminum blocks) material falling off the end of the belt and magnetic (steel blocks) material sticking on the conveyor belt up to where the roller ends or magnetic pull is too weak to continue holding the material.

If you add a simple wall to route the materials, a simple magnetic roller like this can easily sort ferromagnetic metals like iron, nickel and steel from other materials such as plastic, non-ferrous metal, waste etc.

DIY magnetic separation roller

Below is a hands on video where we showcase our simple DIY build for a magnetic roller to separate ferrous metals from plastics and other materials.

Shop Neodymium Magnets

Vast selection of neodymium rare earth magnets perfect for making arrays for eddy currents or specialized Halbach arrays.

3. Eddy current separation

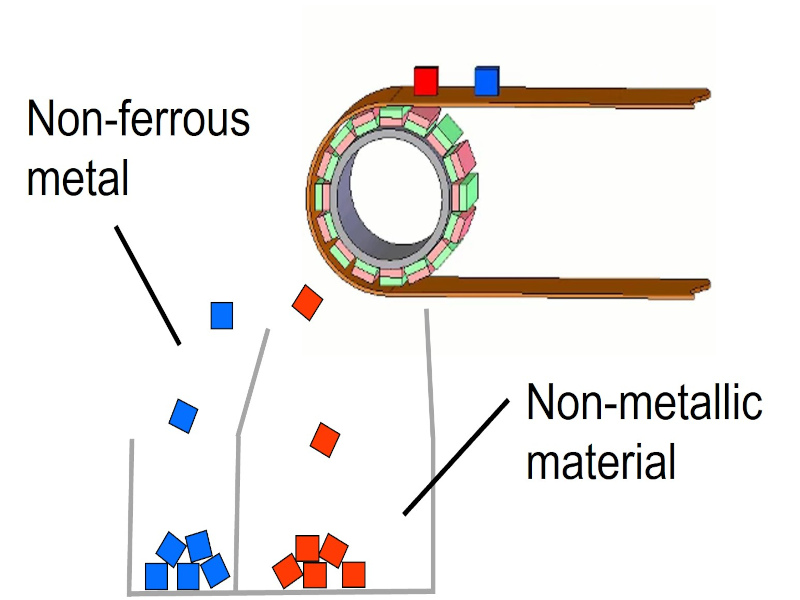

Magnetic separation roller with eddy current

This conveyor belt uses eddy currents to launch (aluminum blocks) off the end of the belt while the (plastic blocks) simply fall down. We accomplished this by adding a stationary tube over the magnets then spinning the magnets at a high velocity. The rapidly changing magnetic fields create a propulsive force in the aluminum which is what propels it forwards off of the conveyor belt while other material falls straight down. This allows the separation of copper, aluminum and other conductive material from things like plastic. Eddy separation is a key technology in the recycling industry and anywhere else certain metals need to be sorted from other materials.

DIY eddy current separation roller

The video below shows off our DIY roller that uses eddy currents from fast revolving magnets to push aluminum parts off the end of our conveyor belt.

4. What are the best magnets for building an eddy current separator?

That's really a general question looking for a specific answer. It depends! The magnets you choose depend on a wide number of variables, including the design of your machine, conveyor belt, desired strength, distance from the magnets to the materials, etc.

We used some BX884DCS countersunk block magnets for our iron separator. Our Countersunk Magnets are popular for this sort of thing, since they are easy to assemble. Most of the actual, industrial separators we've seen use much larger magnets like the 2" x 1" x 1/2" thick BY0X08DCS countersunk block magnets. We chose smaller ones because it was simpler for our scaled-down model.

We used 2" x 3/8" x 1/4" thick BY064 block magnets plain blocks for the Eddy Current Separator shown in the second video. It was a good size for our scale, and they worked well. We actually chose these specific magnets because we had a small stack set aside that had scratched plating. Other similar block magnets sizes would have worked as well.