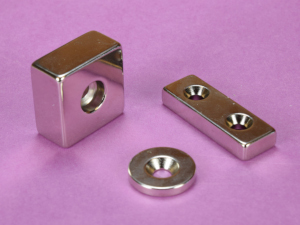

All About Countersunk Magnets

Our line of countersunk magnets are some of our most popular products. Countersunk magnets can be great for so many different applications. This month, we'll take a look at some common applications for countersunk magnets and answer some frequently asked questions about them, including polarity issues, torque data, and screw type/size.

Countersunk magnets - What are they good for?

We've been publishing our monthly blog for about 12 years now, so we have several previous articles that use countersunk magnets. These include:

- Tool Organization

- Magnetic Trains

- Removable Access Panel

- DIY Magnetic Lock

- Magnetic Table Legs

- Shear Force with Doors

- Magnet Sweeper

- Magnetic Doorstops

- Magnetic Cabinet Closures

- X-Wing Miniatures Game Mod

- Light Switch Key Holder

- Fishing Wires Through Walls

- Google Cardboard

- Magnetic Bottle Opener

- Hanging Art on a Wall

Basically, countersunk magnets are good for whenever you need to securely fasten a magnet to an object or surface. Gluing magnets works, but sometimes you need something more rigid, which is where countersunk magnets are great.

FAQ about countersunk magnets

When does polarity matter? If the magnets are attracting to a piece of steel, the polarity doesn't matter. For example, our R822CS-N has the countersunk on the north pole, while the R822CS-S has the countersunk on the south pole. Each pole will equally attract to the steel. The only time polarity matters is if the magnet is attracting to another magnet - which is why we also sell them in pairs, like our R822CS-P.

Should I use another countersunk magnet, or a steel washer? This answer can depend on the application. When using two magnets, there could be alignment issues. You have to make sure the magnets are perfectly aligned, or they might not pull nicely to each other. In our Magnetic Forces article, we show that offset magnets could actually repel each other at a certain point. Using a steel washer can eliminate this, since the magnet will stick anywhere on the steel.

However, as we explain in our Magnets vs. Steel article, you might not get the full pull force between a magnet and a similarly sized steel washer. The washer would need to be about twice as large as the magnet to get 99% of the pull force. So if force or space is an issue, using two magnets might be better.

Does screw material matter? Brass, stainless, or regular steel screws? The screw material doesn't matter too much, don't fret over choosing the right material. In our Magnetic Doorstops article, we did find that using a steel screw slightly increased the force of the magnet, but it might not be a noticeable difference in most applications. Steel screws can be frustrating to use with magnets!

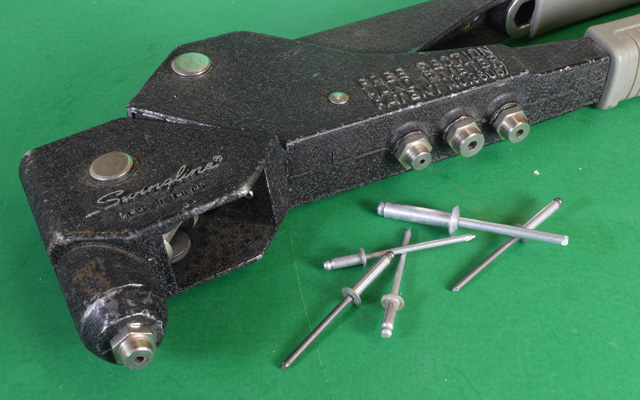

Can the countersunk magnets accept rivets? Yes! For this article, we tested out two different rivet sizes with our countersunk magnets. We found that an 1/8" rivet fits in most #4 or #6 screw holes, and a 3/16" rivet fits most #8 or #10 holes.

| Rivet Size |

Magnets |

| 1/8" rivet |

R622CS-N,

R822CS-N,

RA22CS-N,

B848CS,

B884DCS,

BC82CS-N,

BC84DCS,

BCC4DCS,

BX048CS,

BX082CS-N,

BX088DCS,

BX0X03DCS,

BX884DCS,

BY084DCS |

| 3/16" rivet |

RC22CS-N,

RC24DCS,

RE22CS-N,

RX033CS-N,

RX434DCS,

RX836DCS,

BX0X08DCB,

BY0X04DCS,

BY0X08DCS |

Torque Data

What are the torque specs for countersunk magnets? This is a question we get all the time, and rightfully so. Neodymium magnets are very hard and brittle, they can be broken if mishandled. We've never had a good answer to this question, as there are many different factors that could influence this.

In that Magnetic Doorstops article, we tried over and over again to drive a wood screw with a countersunk magnet, trying to break the magnet, but we couldn't do it. In other projects when we weren't trying to break a countersunk magnet, we broke them when fastening them with screws.

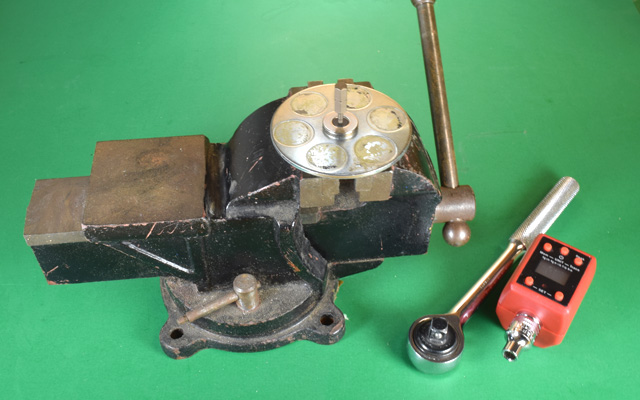

Using a digital torque adapter, we found that we could break all of our 1/8" thick countersunk magnets with about 30 in/lb of force. This was the case with both a square drive flat head wood screw and hex drive flat head machine screw. Phillips drives were designed to limit torque, but they are still capable of breaking a magnet in the right conditions.

Impact can be an issue too - if the screw is driven very quickly into the magnet, this, along with the torque, can shatter the magnet. It's a good idea to set the drill speed and torque low. On our drill, we found that setting our drill torque to 10 drove the screw in efficiently, but stopped from over-torquing and breaking the magnet. This setting is most likely different for different drills, so start low and work your way up.

We found that our 1/4" countersunk magnets, like the RC24DCS and RX434DCS, had much higher limits. In fact, we weren't able to create enough torque in our setup to break them, and even stripped a smaller hex drive. Still be cautious with impact and torque, but thicker magnets seem to handle torque better.

Plastic coated countersunk magnets hold up well to over-tightening, mostly because the 1/32" thick plastic coating takes the force and deforms. So while you probably won't break a plastic coated countersunk magnet with torque, you can deform the coating.

Our Mounting Magnets also have a higher torque rating - once again we weren't able to break any.

Torque Disclaimer!

Use this information to help you make an informed decision, but don't just take our word for it! There are many factors that could influence the result, like screw type, thread aggressiveness, substrate, etc. Set the torque very low and work your way up.