What is Magnetic Separation?

How magnetic separation is used across various industries

1. What is magnetic separation?

Magnetic separation has been a key technology for decades, used to extract magnetic metals from various materials or to enhance separation processes and plays a vital role across numerous industries, where magnets are extensively employed. Magnetic separation remains an invaluable tool for isolating metal from other substances.

Effective material separation is essential for removing contaminants and impurities from production lines. It continues to be one of the most reliable and cost-effective methods available.

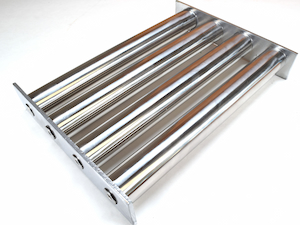

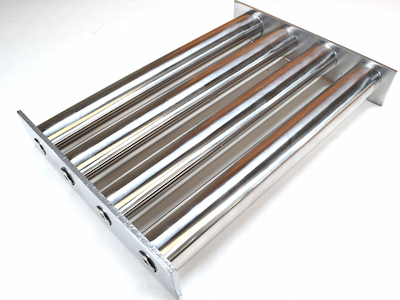

Separation using a magnetic grate and magnetic filter rods

The below video highlights our magnetic filter rods in a magnetic grate setup. These are used to trap ferrous metals from passing through and have a strong uniform field across the entire width. The target material such as food, grains etc. will pass through while all of the ferrous metal debris and contamination is trapped and can be safely removed.

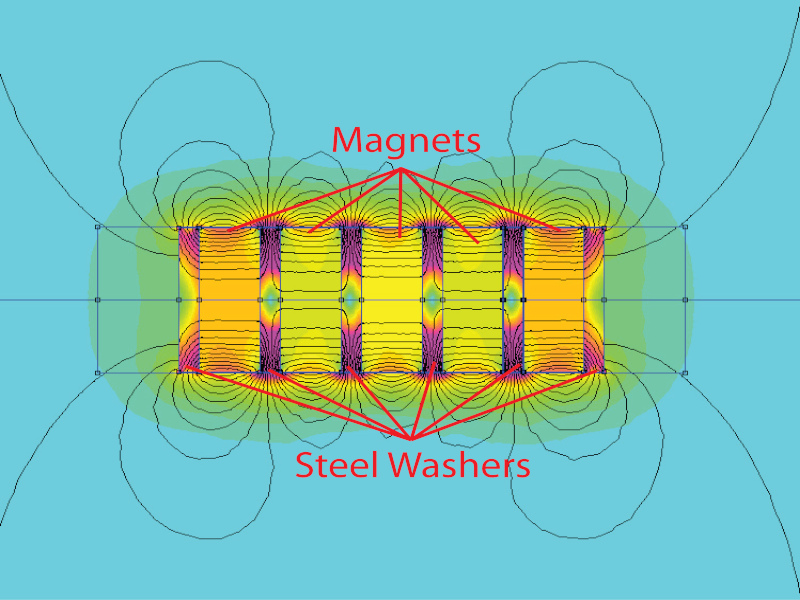

The inside of a filter rod consists of an array of disc magnets alternating with steel washers to concentrate and strengthen the magnetic field uniformly across the entire length. The below pictures show magnetic film revealing the internal disc magnets and washers and a cross-section view showing the internal structure.

2. Where is magnetic separation used?

Separating materials with magnetic attraction or sorting with eddy currents is used extensively across many industries. The below list has examples of just a few applications in major industries.

-

Food Processing - Magnetic filter rods are extensively used in the food processing and animal feed industry to remove ferrous contaminants from food products. This is crucial to ensure product purity and safety, and to protect processing equipment from damage.

-

Pharmaceuticals - Used in the production of pharmaceuticals to remove small metal contaminants from powders and liquids to ensure product purity and compliance with health regulations.

-

Recycling - Recycling facilities use magnets to separate metallic particles from crushed electronic scrap, automotive shred, or other mixed waste streams.

-

Mining - Mining operations use magnets to separate ferrous materials from crushed ore and increase the purity of raw materials.

-

Ceramics - In the ceramics industry, magnetic filter rods help remove fine iron impurities from slips and glazes to help the aesthetics and integrity of ceramic products.

-

Water Treatment - Used to remove ferrous contaminants from water streams in industrial water treatment facilities, protecting equipment from damage and reducing contaminant levels in discharged water.

Explore Separation Magnets

Filter bar magnets and disc and block magnets ideal for magnetic separation!

3. Best magnets to use for magnetic separation

The most ideal magnets for any separator will depend on the type of separator and how it will be used specifically. Many magnets are used as part of an assembly or in an array. Arrays are good for providing stronger and more uniform magnetic fields over a shorter distance.

Most common types of magnets in separator assemblies

-

Filter Rod magnets - Magnetic filter rods are typically a steel tube with an array of disc magnets and steel washers inside. This setup provides a very strong and uniform magnetic field across the entire length; making it deal for magnetic separation and ferrous metal collection and removal. They also feature food grade 304 stainless steel so are safe for food processing applications as well.

-

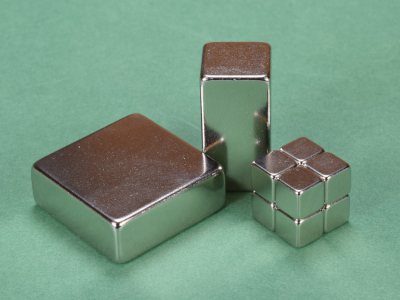

Block magnets - Block magnets are one of the most popular type of magnets used for separation. Their shape allows for maximum coverage in small spaces and are easy to install in rows or an array. They are used everywhere from bar separators across a production process to arrays for eddy current separation.

Block Magnets

Block MagnetsBlock shape great for making rows and arrays for magnetic separation or strong and uniform fields

Shop Now -

Disc magnets - Disc magnets are the magnet of choice for separators like magnetic grates and magnetic drawers etc. that utilize magnetic filter rods to attract ferrous material passing through a confined space.

Most common types of magnetic separators

There are many types and sub-types of magnetic separators out there, but here we will cover 3 of the most popular types.

-

Magnetic grates - Magnetic grates are an assembly using filter rods to make a grate that material needs to pass through. This makes it easy to trap unwanted ferrous scrap and impurities and is the assembly of choice for many industries, including removing contamination in the food industry.

-

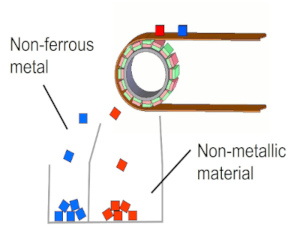

Eddy current separators - Eddy current separators typically consist of arrays of magnets in opposing directions attached to a roller. The eddy currents allow separation of non-ferrous metals such as aluminum and copper.

-

Magnetic arrays - Many other assemblies such as overband, drum and bar separators may utilize an array of magnets. Magnetic arrays are very versatile and can also be found in Halbach arrays, magnetic brooms, magnetic knife blocks and many other places where a strong and uniform magnetic field is needed.

4. Benefits of Magnetic Separation

The adoption of magnetic separation technology offers several advantages:

-

Improved Product Quality - Quality and safety can be improved by removing impurities and contamination from product line.

-

Cost Efficiency - A form of preventive maintenance as ample separation reduces the load on secondary processing equipment, lowering maintenance costs or preventing them to begin with. They also have fewer moving parts that further reduce maintenance costs.

-

Environmental Impact - Separation is used in many recycling processes to separate materials for reuse which can help reduce waste or scrap costs.

-

Energy Efficiency - Separators generally requires less energy compared to other separation methods. Many separators can function with gravity and magnetic fields alone; leading to reduced costs for installation and utility overhead.